#GRAIN BOUNDARY FREE#

Where e refers to electron charge, ε 0 is the permittivity of free space, ε gb is the permittivity of the grain boundary region, N s is the concentration of surface acceptor states, and N 0 is the concentration of charged species in the depletion layer. The barrier at the grain boundary (ϕ 0) is given by ϕ 0 = e 2 N s 2 8 𝜀 0 𝜀 g b N 0 , A two-dimensional electron trap exists along the grain boundary where acceptor states attract electrons from the bulk resulting in an electron depletion layer and consequently a potential barrier. acceptor states, along the grain boundaries of BTO, which exhibits different electrical properties from those of the bulk phase.

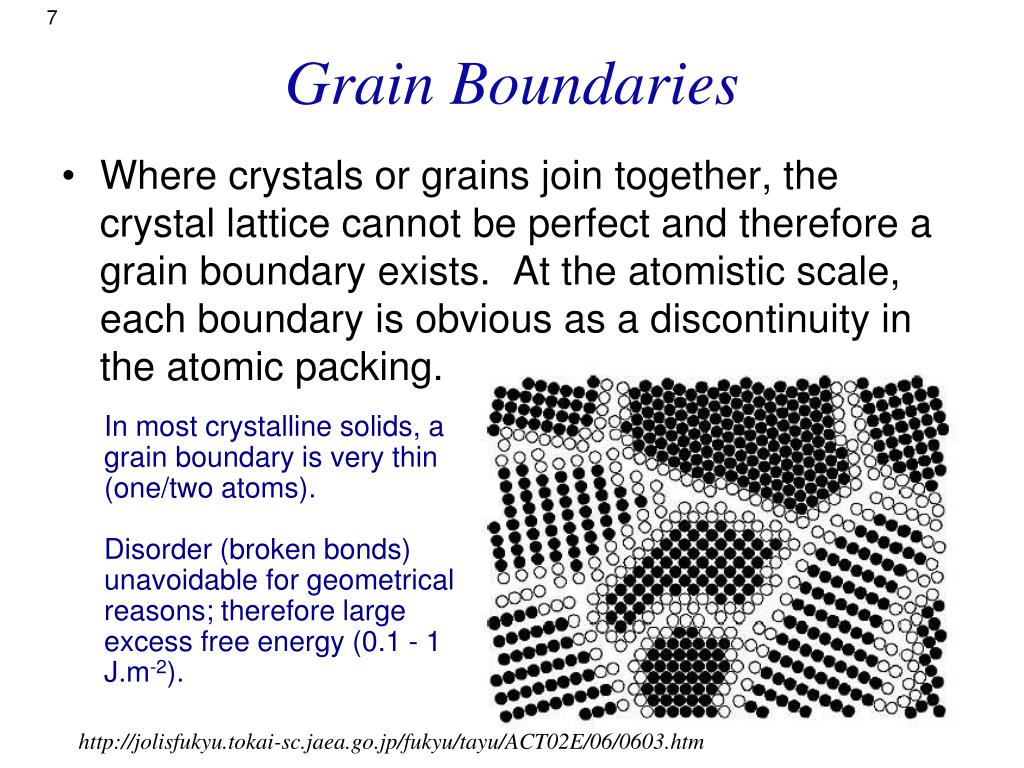

), there is a bi-dimensional layer of electron traps, i.e. According to the original Heywang model 7 7. The most accepted among these models is the Heywang-Jonker model, which states that the presence of a potential barrier at the grain boundaries is responsible for enhanced resistivity of the boundary in comparison to the grain interior. with rich microstructures and an equally interesting domain structure embedded within grains, and several models have been proposed to explain the observed experimental behavior. It was identified quite early that the effect is dominant in polycrystalline samples, 6 6. Over the past 50 years, research on the PTCR effect has focused on compositional and structural issues that govern the electrical properties. (84)90046-5 Among the various materials exhibiting a PTCR effect to date, the most favored material group is BaTiO 3 (BTO) based compounds where the temperature at which this switch in behavior occurs, near the ferroelectric-paraelectric Curie transition temperature (T C), and the magnitude of the switch can be controlled and optimized via the addition of different dopants and/or changes in the processing conditions. Understandably, this effect has found extensive applications in sensing technologies such as self-regulating heating elements, current sensors, and sensors for the detection of air flow, liquid level, and temperature changes. The Positive Temperature Coefficient of Resistivity (PTCR) effect is a property found in polycrystalline materials which produce a switch from a low resistance semiconducting state to a higher state of resistance in response to either internal or external heating. These results validate the critical link between optimized PTC performance and higher local polarization at grain boundaries in this specific ceramic system and suggest a novel route towards engineering devices where an interface layer of higher spontaneous polarization could lead to enhanced PTC functionality. Aberration-corrected scanning transmission electron microscopy and electron energy loss spectroscopy reveal new evidence of Pb-rich grain boundaries symptomatic of a higher net polarization normal to the grain boundaries compared to the purer grain interiors. Here we present direct visualization and nanoscale mapping in a commercially optimized BaTiO 3–PbTiO 3–CaTiO 3 PTC ceramic using Kelvin probe force microscopy, which shows that, even in the low resistance ferroelectric state, the potential drop at grain boundaries is significantly greater than in grain interiors. However, direct nanoscale resistance mapping to verify this model has rarely been attempted, and the potential approach to engineer polarization states at the grain boundaries, that could lead to optimized positive temperature coefficient (PTC) behavior, is strongly underdeveloped. Current understanding of the behavior hinges on the role of grain boundary resistance that can be modified by polarization discontinuities which develop in the ferroelectric state. Despite being of wide commercial use in devices, the orders of magnitude increase in resistance that can be seen in some semiconducting BaTiO 3-based ceramics, on heating through the Curie temperature (T C), is far from well understood.

0 kommentar(er)

0 kommentar(er)